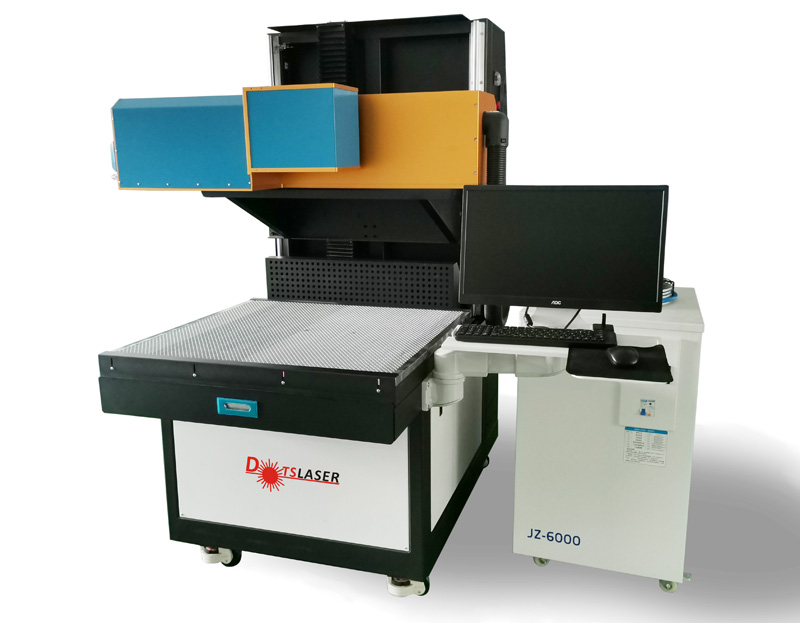

CO₂ Laser Engraving on Marble

Co₂ laser engraver can well mark on hard marble, this machine for marble offers a wide range of benefits. One of the primary advantages is the precision of the machine, which ensures that every engraved image is accurate and flawless. This technology also allows for a high level of detail, making it possible to create intricate designs or text engravings.

Video shows:

Machine Features

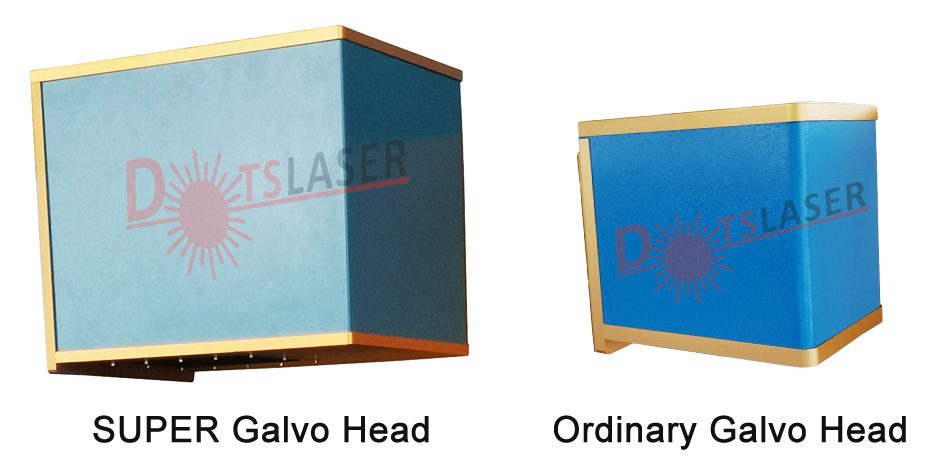

01/Precision and accurate marking:

Laser technology is faster in marking detailed designs than traditional painting, making it ideal for intricate patterns and images.

02/Durability:

Marble is a strong and long-lasting material,use laser marking ensures that engravings remain intact over time.

03/Versatility:

Suitable for various applications, from decorative pieces to functional items like plaques and signage.

04/Customization:

You can personalize items follow your heart,including names, dates, or specific designs, making them unique.

Parameter:

Laser tube parameters | Max Output Capacity | 250W |

| Nominal Peak Powe | ≥450W | |

| Mode Quality | M2≤1.2 | |

| Duty Cycle Limit | ≤70% | |

| Laser Type | CO2 | |

| Laser Wavelength | 10.6μm | |

Marking performance | Marking Format | Pattern,Word,Bar code,QRcode,Date,Serial Number |

| Marking Character Types | Pattern and words of vectordiagram & bitmap | |

| Marking Area | 400X400-700X700(mmXmm) Adjustable | |

| Marking Depth | 0-5mm (According to the materials) | |

| Marking Speed | <7000mm/s | |

| Min Line Width | 0.3mm(According to the materials) | |

| Min Character | 0.4mm | |

| Repeat Positioning Accuracy | 0.01mm | |

| Machine information | Total Power | <6KW |

| Power Supply | AC220V/50Hz/30A | |

| Cooling Way | Constant temperature water cooling unit | |

| Working Temperature | 15-30℃ | |

| Working Humidity | <75 No condensation | |

| Working Environment | Without dust, without vibration | |

| Machine Packing Size | 1010*1340*1740mm | |

| Control cabinet packing size | 1060*660*1100mm | |

| Chiller packing size | 660*760*1080mm |

Applicable Industries:

Three Axis Dynamic CO2 Laser Marking Machine is widely suitable for the industries, such as Heat Transfer film (paillette, TPU materials, Reflective transfer film, etc.), leather, wooden box, paper card, clothes denim, illuminator,Mobile communications, mould, precision machinery, IT Digital shell, Military aviation components, handicrafts, Advertisement decoration, etc.

What's the process of laser engraving marble?

1. Prepara your design: Create or import your design using graphic software compatible with your laser engraver.

2. Material Setup: Place the marble on the laser engraver's bed and secure it to prevent movement.

3. Adjust correct focus: Use the autofocus feature to ensure the laser beam is properly focused on the marble surface.

4. Set engraving: Adjust the laser settings based on the marble type and desired depth of engraving.

5. Engraving Execution: Start the engraving process, monitoring progress to ensure accuracy.

6. Finishing Touches: When you finish engraving,remember to clean the marble in case dust hide in marble.

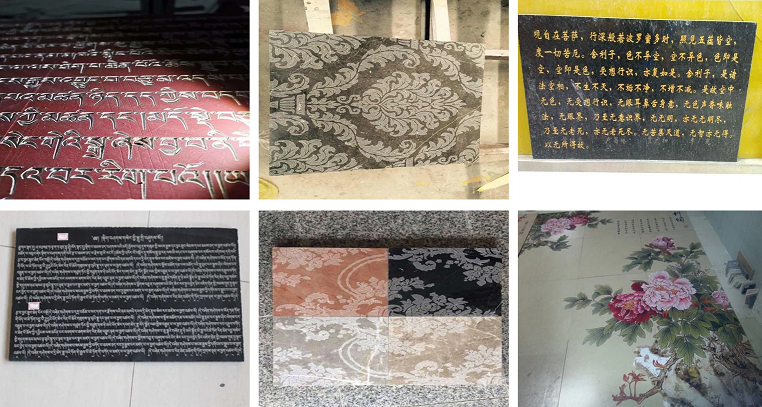

Application Of Laser Engraving Marble:

1. Use for Decorative.

It can be used as wall art, photo frames, or even personalized gifts. The intricate designs and high-resolution engravings on the marble make it stand out and add a touch of elegance to any room.

2. Used for signage.

Its durability and elegant appearance make it an excellent choice for outdoor signage in front of businesses or even as address plates for homes.

3. Used for memorial purposes.

It is a fitting tribute to loved ones and can be used as a headstone or personalized monument. The precision of the laser engraving ensures clarity and longevity of the memorial, making it a lasting tribute.

Samples:

Shipment and package

Certificate

After service

1. Quality assurance and after-sales service

The warranty period of the equipment shall be 12 months since the equipment be used by the customers, the installation and debugging is completed and the equipment is accepted by the demander.

Dotslaser attaches great importance to the after-sales service work of the product, once the product is delivered to the user, the company immediately established the user after-sales service file,

and regularly track the user's product use status, solve and answer all the problems of the user, received the user's notification information about the equipment failure,

the company's workers can make a rapid response within 2 hours. If the telephone guidance is difficult to troubleshoot, our company's technical staff can arrive at the customer site

within 24 hours to provide support.

2. Installation and debugging

Before machine installation, our factory will offer you a basic structure installation file,the good need 2 weeks delivery to you there , the engineers of Dotslaser will arrive at your site and inspect the machine again.

Comfirm all the conditions meet the installation and commissioning requirements of the equipment, the equipment will transport in time.

The installation and commissioning time of the equipment is about five working days, the first three days are connected to the use of the system, and the system is operational after the service project.

The engineer will train qualified operators on basic maintenance procedures and general operating characteristics of the equipment in the next two days

3. Service support

If there has any problem with any part of the system during the warranty period, Dotslaser well-trained service engineers are ready to provide cellphone call or begin on-site service,

if the machine has any problem during the warranty period,please contact us directly !